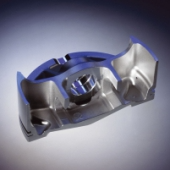

Omega Piston set for Volvo B230 Turbo

| Comp Height | 38,9 mm |

| Dome Dish (cc) | 14 cm³ |

| Comp Ratio | 8,2:1 |

| Pin | 23 mm |

| Bore | 96.5mm |

Kit Contains

4pcs 96.5mm Omega Forged pistons

4pcs heavy duty wrist pins / Gudgeon pin

4sets high performance piston ring packs

Since its conception in 1972, Omega Pistons have been at the forefront of all the premier motorsport categories. Omega are world leaders in forged performance pistons and are justifiably proud of their success in international motorsport.

Forgings A forging is still the best way to manufacture a piston, not just from a production point of view but for the strength of the piston. There are certain areas where a piston machined from solid is marginally better than a forging but the strength benefits of a forging far outweigh any benefits of a fully machined piston. You get excellent grain structure when a piston is forged correctly, the way we do it. In a fully machined piston you don't get any true grain flow structure as you are using the material as it is cut from the bar. When you forge the material you create optimal molecular alignment within the material and this is what gives the piston its strength.

In our experience we have found that the people who are promoting fully machined pistons cannot offer forgings, it is much easier and cheaper to buy a machine with 3D capabilities than it is to buy and set up a forging plant, then there is the experience and skill required to create the perfect forging, it isn't easy, this is the reason they are saying "fully machined is the best", they can't offer the best so they say that their way is the best. |

|

| |

|

| | Materials All forging, casting and machining is processed in-house to ensure that the highest standards are maintained. Omega's in house heat treatment plant ensures the optimum molecular grain structure and the highest possible strength for the particular material being used.

Pistons can be produced in various alloys according to the design and application specifications, the most common material is 2618A aerospace alloy. |

|